Product Description

|

Product Name |

Flexible Fluid Chain Jaw Flange Gear Rigid Oldham Servo Motor Shaft Coupling |

|

Material |

Aluminum alloy,stainless steel |

|

Surface treatment |

Natural color anode |

|

Customized service |

Support light customization and logo customization |

| Size | To be customized |

|

Remarks |

The default engraving brand name and size of the product. If you need not engraving, please contact the customer service for comments |

| Packaging Details | Carton box with anti-static package,carton plus with wooden case. |

| Main Products | Shaft Parts, Timing Belt Pulley, Gears, CNC Machining Parts, Sheet Metal Fabrication |

| Certifications(2) | ISO9001:2015, IPMS |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms |

| Supply Ability | 100000 Piece/Pieces per Month |

| Dimension | oem provided |

| Surface finish | anodized |

| Lead Time | 25 days |

| Application | Furniture,cabinet |

| Custom | OEM and ODM services are welcome,we can make cutom LOGO and products according to customer’s requests. |

| Quality control Our | Finished product inspection,Warranty available |

| service | Swiss machining;deburring;lathe/turning;5 axis;micromachining |

| Color |

silver,gold,black,red,bulue,and according to the customer requests. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How does the chain size affect the performance of a chain coupling?

The chain size has a significant impact on the performance of a chain coupling. The size of the chain refers to the physical dimensions of the roller chain used in the coupling, including the pitch, roller diameter, and width. Here are some key ways in which the chain size affects the performance of a chain coupling:

- Torque Capacity: The chain size directly affects the torque capacity of the chain coupling. Larger chain sizes are generally capable of transmitting higher torque loads due to their increased contact area and greater strength. Smaller chain sizes, on the other hand, have lower torque capacities and are suitable for applications with lighter torque requirements.

- Speed Capability: The chain size also influences the speed capability of the chain coupling. Larger chains can typically handle higher rotational speeds without experiencing issues such as excessive vibration or centrifugal forces. Smaller chain sizes may have limitations in terms of maximum allowable speeds and may not be suitable for high-speed applications.

- Service Life: The selection of an appropriate chain size is crucial for achieving the desired service life of the chain coupling. If the chain is undersized for the application, it may experience premature wear, fatigue, and ultimately fail under the operating conditions. Conversely, using an oversized chain may result in unnecessary costs, increased weight, and reduced efficiency.

- Space Constraints: The physical size of the chain can also impact the overall dimensions and installation requirements of the chain coupling. Larger chain sizes may require more space for proper installation, including clearance for the chain links and sprockets. In applications with limited space, choosing a smaller chain size may be necessary to ensure proper fit and operation.

- Compatibility: The chain size should be compatible with the sprockets and other components of the chain coupling. It is important to ensure that the chain and sprockets are designed to work together, with matching dimensions and tooth profiles. Using an incompatible chain size can lead to poor engagement, increased wear, and reduced overall performance.

When selecting the appropriate chain size for a chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, space limitations, and compatibility with other components. Consulting the manufacturer’s recommendations and guidelines is crucial to ensure the optimal chain size selection for the desired performance, reliability, and longevity of the chain coupling.

How to install a chain coupling?

Proper installation of a chain coupling is crucial for ensuring its optimal performance and longevity. Here are the steps to follow when installing a chain coupling:

-

Prepare the Work Area: Before beginning the installation, ensure that the work area is clean and free from any debris or contaminants. This will help prevent any damage to the coupling components during installation.

-

Inspect the Components: Carefully inspect the chain coupling components, including the sprockets, roller chain, connecting pins, and bushings or bearings. Check for any signs of damage or wear. Replace any components that are worn or damaged.

-

Position the Coupling: Position the coupling on the shafts that need to be connected. Ensure that the shafts are aligned properly and the coupling is centered between them.

-

Install the Sprockets: Slide the sprockets onto the shafts, with the teeth facing each other. Make sure the sprockets are securely seated on the shafts and aligned with each other.

-

Connect the Roller Chain: Loop the roller chain around the sprockets, ensuring that it is properly engaged with the sprocket teeth. Connect the ends of the roller chain using the connecting pins. Insert the connecting pins through the pin holes in the chain links and secure them with retaining clips or other fasteners.

-

Tension the Chain: Adjust the tension of the roller chain to the manufacturer’s specifications. The chain should have the appropriate amount of slack to allow for smooth operation and accommodate misalignment but should not be too loose or too tight. Follow the manufacturer’s guidelines for determining the correct chain tension.

-

Secure the Bushings or Bearings: If the chain coupling uses bushings or bearings, ensure they are properly installed in the bores of the sprockets and provide a secure and smooth rotation of the shafts.

-

Apply Lubrication: Apply the recommended lubricant to the roller chain and sprockets. Proper lubrication is essential for reducing friction, wear, and noise, and it helps ensure smooth operation of the chain coupling.

-

Check Alignment and Rotation: Once the chain coupling is installed, check the alignment of the shafts and the rotation of the coupling. Verify that the coupling rotates smoothly without any binding or interference.

-

Inspect and Test: After installation, thoroughly inspect the entire chain coupling assembly. Look for any signs of misalignment, unusual noise, or vibration. Test the coupling’s operation by running the machinery at a low speed and gradually increasing to the normal operating speed. Monitor the coupling for any issues or abnormalities.

Following these installation steps will help ensure a proper and secure installation of the chain coupling, promoting efficient power transmission and minimizing the risk of premature failure or damage.

What are the disadvantages of chain couplings?

-

Backlash: Chain couplings can exhibit a certain degree of backlash or play due to the clearances between the chain rollers and the sprocket teeth. This can result in reduced precision and accuracy in applications where precise motion control is required.

-

Noise and Vibration: The engagement between the chain and sprockets can generate noise and vibration during operation. This can be problematic in applications where noise reduction is important or where excessive vibration can affect the performance or integrity of the machinery.

-

Maintenance Requirements: While chain couplings are relatively easy to maintain, they still require regular attention. Lubrication of the chain and sprockets is essential to reduce wear and friction. Additionally, periodic inspection and adjustment of chain tension are necessary to ensure proper operation. Neglecting maintenance tasks can lead to premature wear, decreased efficiency, and potential coupling failure.

-

Space and Weight: Chain couplings occupy a certain amount of space due to the presence of sprockets and the length of the chain. In applications with space constraints, the size of the coupling may limit its usability. Additionally, the weight of the coupling components can be a consideration in applications where weight reduction is important.

-

Limitations in High-Speed Applications: Chain couplings may have limitations in high-speed applications. At high rotational speeds, the centrifugal forces acting on the chain and sprockets can increase, potentially causing stress and reducing the efficiency of the coupling. In such cases, alternative coupling designs, such as gear or flexible shaft couplings, may be more suitable.

-

Wear and Service Life: Like any mechanical component, chain couplings are subject to wear over time. The chain and sprockets can experience gradual wear and elongation, requiring eventual replacement. The service life of a chain coupling depends on factors such as the operating conditions, maintenance practices, and the quality of the components used.

While chain couplings offer several advantages, it is important to consider these disadvantages and evaluate their impact based on the specific application requirements. Proper maintenance, periodic inspection, and careful consideration of design factors can help mitigate these disadvantages and ensure optimal performance and longevity of the chain coupling.

editor by CX 2024-03-26

China Best Sales Kc5018 Industrial Transmission Gear Reducer Conveyor Parts Chain Couplings

Product Description

|

Chain |

Chain No. |

D Bore Dia | Dimension | Inertia

×10-3 kgf·m2 |

Approx Weight

kg |

Casing | ||||||||

| Min mm | Max mm | L

mm |

I

mm |

S

mm |

d1 mm |

d2 mm |

C

mm |

Dimension | Approx Weight

kg |

|||||

| A mm |

B mm |

|||||||||||||

| KC-5018 | 50-2X18 | 16 | 45 | 99.7 | 45.0 | 9.7 | 70 | 106 | 18.1 | 15.420 | 3.8 | 122 | 85 | 0.8 |

Chain couplings

The Chain coupling is composed of a duplex roller chain and a pair of coupling sprockets. The function of connection and detachment is done by the joint of chain. It has the characteristic of compact and powerful, excellent durability, safe and smart, simple installation and easy alignment. The Xihu (West Lake) Dis.hua Chain coupling is suitable for a wide range of coupling applications.

Roller chain( Coupling Chains)

Though Hans Renold is credited with inventing the roller chain in 1880, sketches by Leonardo da Vinci in the 16th century show a chain with a roller bearing.Coupling chains)Coupling chains

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient[1] means of power transmission.

| Chain No. | Pitch

P mm |

Roller diameter

d1max |

Width between inner plates b1min mm |

Pin diameter

d2max |

Pin length | Inner plate depth h2max mm |

Plate thickness

Tmax |

Transverse pitch Pt mm |

Tensile strength

Qmin |

Average tensile strength Q0 kN |

Weight per piece q kg/pc |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lmax mm |

Lcmax mm |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4012 | 12.7-0-0. p. 211. Retrieved 17 May 2-0-0. p. 86. Retrieved 30 January 2015. Green 1996, pp. 2337-2361 “ANSI G7 Standard Roller Chain – Tsubaki Europe”. Tsubaki Europe. Tsubakimoto Europe B.V. Retrieved 18 June 2. External links Wikimedia Commons has media related to Roller chains. The Complete Xihu (West Lake) Dis. to Chain Categories: Chain drivesMechanical power transmissionMechanical power control Why Choose Us

What are the common materials used in chain couplings?Chain couplings are commonly made from various materials that offer the necessary strength, durability, and wear resistance required for transmitting torque between shafts. The choice of materials depends on factors such as the application requirements, operating conditions, and the specific design of the coupling. Here are some common materials used in chain couplings:

It’s important to note that the materials used in chain couplings may vary depending on the specific manufacturer, coupling design, and application requirements. It is recommended to consult the manufacturer’s specifications and guidelines to determine the appropriate materials for a particular chain coupling. Additionally, in some cases, chain couplings may incorporate a combination of different materials, such as steel for the sprockets and roller chain, and elastomers for the flexible elements. This hybrid construction allows for optimized performance, balancing strength, flexibility, and damping characteristics. Overall, the selection of materials for chain couplings is crucial to ensure reliable and efficient power transmission while considering factors such as load capacity, operating conditions, and the desired service life of the coupling.

What are the key components of a chain coupling?A chain coupling consists of several key components that work together to transmit power and accommodate misalignments. Here are the main components of a chain coupling:

These components work together to provide a reliable and efficient power transmission in chain couplings. The sprockets engage with the roller chain, and as one sprocket rotates, it drives the chain, causing the other sprocket and the connected shaft to rotate. The roller chain and its components, along with lubrication, allow for flexibility and compensation of misalignment between the shafts.

What are the disadvantages of chain couplings?

While chain couplings offer several advantages, it is important to consider these disadvantages and evaluate their impact based on the specific application requirements. Proper maintenance, periodic inspection, and careful consideration of design factors can help mitigate these disadvantages and ensure optimal performance and longevity of the chain coupling.

China manufacturer & factory supplier for Buy in Arak Iran oem china company electric worm wheel drive working gear reduction box variator motor With high quality best price & service

corrosion- and put on-resistant coiled tubing injector roller chain assemblies for the oil and gas industries. Obtainable in single and double pitch travel chain sorts with different sizes and energy score. Features incorporate zinc-nicWe warmly welcome the friends from all the planet!kel and non-hexavalent chromate protecting exterior coating, electrochemically bonded, and interference in shape include plates. The group is centered on making all assortment of regular roller chains and sprockets, gears & gearboxes, this kind of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just offered its goods all in excess of china, but also marketed a lot more than 65% merchandise to oversees, like Europe, America, South-east Asia, and it also has established up storage logistics in places like Europe.

Overview

Fast Details

Offer Potential

Packaging & Shipping

On the internet Customization

Get oem china organization electrical worm wheel generate functioning equipment reduction box variator motor

Q1.How to pick a variator motor which meets our requirement?

Q2.How is your price tag? Can you supply any low cost?

Q3.Do you offer any visiting?

This autumn.When is the ideal time to speak to you?

Q5.How extended will it take for the lead time?

China manufacturer & factory supplier for factory in Paris France manufacturer for High quality custom pinion gear planetary spur for tractor With high quality best price & service

ISO 9001 licensed manufacturer of precision roller chains. Sorts include one and numerous strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. we have acquired the believe in of buyers throughout the world. a specialised provider of a total selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

Source Capability

Packaging & Shipping and delivery

On-line CustomizationThe good quality of products is for us and for our clients of higher significance. This is why we use European manufactured elements in our goods. We also complete consistent manage of incoming supplies and the control of finished goods. In our organization we operate in accordance to ISO 9001.

We At any time-Electrical power Team with 4 branches in excess of 1200 personnel is 1 of the largest transmission elements and machining things makers in China Merchandise Description

Product Description:

We specialised in producing auto gears , motorbike gears, gearbox, specific vehicle (energy takeoff, snowmobiles, engineering automobiles) gears, generator add-ons, stainless metal ice crusher and so forth.

China manufacturer & factory supplier for China in Kerman Iran manufacturer for cycloidal pin wheel gear reducer for conical mixer machine With high quality best price & service

Distributor of precision roller chains manufactured from carbon metal. Accessible with .two hundred to 1.875 in. roller dia. Flat top, multi-flex and conveying chains are also supplied.EPG will constantly adhere to it organization spirit of becoming practical, revolutionary, effective and outstanding to make the best global transmission generate.

Overview

Quick Specifics

EPG manufacturer rotocultivator ploughshares in T. line have been selected as the Nationwide Rotary Tillage Machinery Sector “Best Brand Goods” in 2007 by Rotocultivator Department of China Agricultural Machinery Sector Association.

Offer Capacity

Packaging & Shipping In our revenue plan we offer regular and vast-angle PTO travel shafts. Regarding the customers’ requirements there are various sizes, lengths and security aspects (clutches) obtainable.

On the web Customization

Merchandise Description

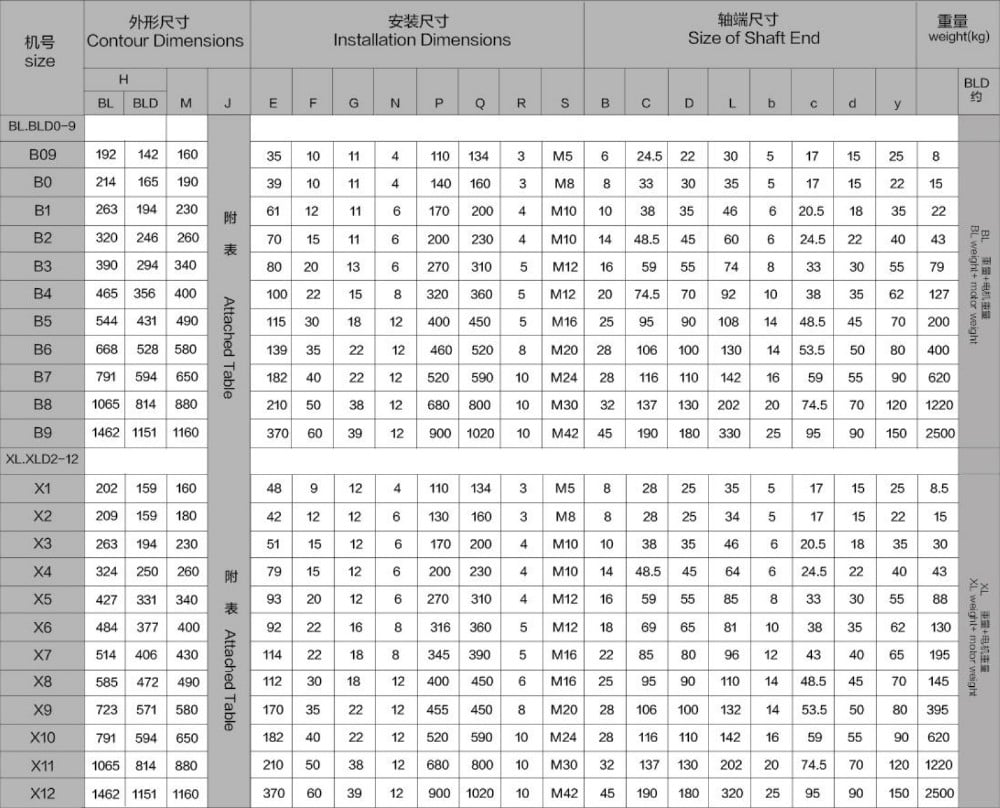

Cycloidal equipment reducer is a principle adopted K-H-V Planetary Equipment less revolutionary equipment. Its transmission process as follows : enter shaft outfitted with a a hundred and eighty-degree dislocation of the double eccentric sets, changed with two eccentric turn as a roller bearing arm, the development of H-, two cycloid spherical gap at the heart shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing period, comprising a variation of the tooth meshing with the gearbox.

Principal AttributesAll planetary cycloidal reducer rotating device can be divided into 3 components:input element,deceleration element and output part. Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,geared up with two ball bearings on the eccentric sleeve,the development of H two cycloid gear middle gap is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid equipment and pin gear ring of equipment meshing,considerably less undesirable tooth meshing reduction system to form,(in buy to reduce friction,in little ratio of pace reducer,the needle with needle enamel on the equipment established).

Traits:1.Cycloid reducer massive reduction ratio, higher effectiveness: a reduction gear ratio is 9~87, the two-phase reduction gear ratio is 121 ~ 5133, multistage mix can achieve tens of countless numbers, and the needle tooth meshing line variety rolling friction, the meshing area no relative sliding, so a reduction efficiency of 94%.

Our Company

HangZhouYinxin Electromechanical Facilities Co. LtdHangZhouYinxin Electromechanical Equipment Co., Ltd.is a present company integrating improvement, layout, creation and sales,Principal promoting products include reducer motor,water pump,design machinery and parts,bearings,components and electrical tools,plastic goods,Labour defense appliance.Our firm usually comply with the procedure concept which is made up of people-oriented, innovation as the soul,be geared up for hazard in times of peace, unremitting……

Software area

Certifications

Income territory

Packing & Shipping and delivery

FAQ

Q1: Are you buying and selling organization or producer ?A: We are a maker in ZJ China.welcome to our manufacturing unit to have a check out.

Q2: How we decide on models and technical specs?A:You can email us the sequence identify & code (for illustration: WJ collection worm gearbox) as properly as prerequisite particulars, this kind of as motor energy, output pace or ratio, provider issue or your application…as much info as achievable. If you can supply some images or drawings, it is far better.

Q3: How is your price tag? Can you supply any price cut?A: We will give the greatest cost we can foundation on your requirements and the portions.

This autumn: How lengthy must I wait around for the comments soon after I ship the enquiry?A: Inside of twelve hrs.

Q5: What is your solution warranty period?A:We supply 1 year guarantee because the vessel departure date still left China.

Q6: What industries are your gearboxes becoming used?A:Our gearboxes are commonly applied to metallurgical equipment, mining gear, automation products, foodstuff machinery, packaging equipment, tobacco equipment and so on.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||