Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CHINAMFG requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the safety considerations when using chain couplings?

When using chain couplings, it is important to consider several safety aspects to ensure the protection of personnel, equipment, and the overall system. Here are some key safety considerations when using chain couplings:

- Proper Installation: Ensure that the chain coupling is correctly installed according to the manufacturer’s instructions. Improper installation can lead to misalignment, inadequate lubrication, or other issues that can compromise safety and performance.

- Alignment and Maintenance: Regularly inspect and maintain the chain coupling to ensure proper alignment, lubrication, and tension. Misalignment or lack of maintenance can result in premature wear, excessive vibration, and potential coupling failure, posing safety risks.

- Guarding: Consider implementing appropriate guarding measures to protect personnel from coming into contact with the rotating chain coupling components. This is particularly important in applications where there is a risk of entanglement or pinch points.

- Lockout/Tagout: Follow proper lockout/tagout procedures when performing maintenance or repairs on machinery equipped with chain couplings. This ensures that the equipment is safely de-energized, preventing accidental startup or release of stored energy.

- Load Capacity: Do not exceed the recommended load capacity of the chain coupling. Overloading the coupling can lead to excessive stress, premature failure, and potential hazards. Consider the dynamic loads, shock loads, and any transient conditions that the coupling may experience during operation.

- Environmental Factors: Evaluate the operating environment and consider any specific safety considerations related to temperature, humidity, corrosive substances, or other environmental factors. Take appropriate measures such as using suitable materials or protective coatings to ensure the coupling’s integrity and safety.

- Training and Awareness: Provide adequate training to personnel who operate or work near chain couplings. Ensure that they understand the potential hazards, safety procedures, and the importance of following manufacturer’s guidelines and industry best practices.

- Emergency Stop: Implement an emergency stop system or device that can quickly halt the machinery in case of an emergency or imminent danger. This allows for immediate shutdown and can help prevent accidents or injuries.

It is essential to consult the manufacturer’s documentation, safety guidelines, and applicable industry standards to ensure compliance with the recommended safety practices for chain couplings. By prioritizing safety considerations, potential risks can be minimized, and the overall reliability and performance of the chain coupling system can be enhanced.

How to install a chain coupling?

Proper installation of a chain coupling is crucial for ensuring its optimal performance and longevity. Here are the steps to follow when installing a chain coupling:

-

Prepare the Work Area: Before beginning the installation, ensure that the work area is clean and free from any debris or contaminants. This will help prevent any damage to the coupling components during installation.

-

Inspect the Components: Carefully inspect the chain coupling components, including the sprockets, roller chain, connecting pins, and bushings or bearings. Check for any signs of damage or wear. Replace any components that are worn or damaged.

-

Position the Coupling: Position the coupling on the shafts that need to be connected. Ensure that the shafts are aligned properly and the coupling is centered between them.

-

Install the Sprockets: Slide the sprockets onto the shafts, with the teeth facing each other. Make sure the sprockets are securely seated on the shafts and aligned with each other.

-

Connect the Roller Chain: Loop the roller chain around the sprockets, ensuring that it is properly engaged with the sprocket teeth. Connect the ends of the roller chain using the connecting pins. Insert the connecting pins through the pin holes in the chain links and secure them with retaining clips or other fasteners.

-

Tension the Chain: Adjust the tension of the roller chain to the manufacturer’s specifications. The chain should have the appropriate amount of slack to allow for smooth operation and accommodate misalignment but should not be too loose or too tight. Follow the manufacturer’s guidelines for determining the correct chain tension.

-

Secure the Bushings or Bearings: If the chain coupling uses bushings or bearings, ensure they are properly installed in the bores of the sprockets and provide a secure and smooth rotation of the shafts.

-

Apply Lubrication: Apply the recommended lubricant to the roller chain and sprockets. Proper lubrication is essential for reducing friction, wear, and noise, and it helps ensure smooth operation of the chain coupling.

-

Check Alignment and Rotation: Once the chain coupling is installed, check the alignment of the shafts and the rotation of the coupling. Verify that the coupling rotates smoothly without any binding or interference.

-

Inspect and Test: After installation, thoroughly inspect the entire chain coupling assembly. Look for any signs of misalignment, unusual noise, or vibration. Test the coupling’s operation by running the machinery at a low speed and gradually increasing to the normal operating speed. Monitor the coupling for any issues or abnormalities.

Following these installation steps will help ensure a proper and secure installation of the chain coupling, promoting efficient power transmission and minimizing the risk of premature failure or damage.

How to select the right chain coupling for a specific application?

Choosing the appropriate chain coupling for a specific application involves considering various factors to ensure optimal performance and reliable power transmission. Here are some key steps to guide you in the selection process:

-

Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as the torque load, speed, misalignment conditions (angular, parallel, axial), and environmental conditions (temperature, moisture, presence of corrosive substances).

-

Determine Torque and Speed Requirements: Calculate or estimate the torque and speed requirements of the application. This information is crucial in selecting a chain coupling that can handle the transmitted torque and operate effectively at the required speed range.

-

Evaluate Misalignment Compensation: Assess the expected misalignment conditions in the application. Determine the magnitude of angular, parallel, and axial misalignments that the chain coupling needs to tolerate. This will help in selecting a coupling design that can accommodate the anticipated misalignment without compromising performance or causing excessive stress on the machinery.

-

Consider Space Limitations: Evaluate the available space for the chain coupling. Measure the shaft-to-shaft distance and ensure that the selected coupling can fit within the available space without interference with other components or structures.

-

Assess Environmental Factors: Take into account the environmental conditions in which the chain coupling will operate. Consider factors such as temperature extremes, humidity, presence of dust or debris, and exposure to corrosive substances. Choose a chain coupling that is designed to withstand these conditions and is made from materials that offer adequate corrosion resistance.

-

Consult Manufacturer Specifications: Review the specifications and technical information provided by reputable chain coupling manufacturers. Pay attention to factors such as torque ratings, speed limits, misalignment capabilities, material compatibility, and recommended maintenance practices.

-

Consider Maintenance Requirements: Evaluate the maintenance requirements of the chain coupling. Assess factors such as lubrication needs, ease of inspection, and adjustment procedures. Choose a coupling that aligns with the maintenance capabilities and resources available in your application.

-

Seek Expert Advice if Needed: If you are uncertain about the selection process or have specific application requirements that need expert guidance, consult with knowledgeable engineers or technical representatives from the coupling manufacturer. They can provide valuable insights and recommendations based on their expertise and experience.

By following these steps and considering the specific application requirements, you can select the right chain coupling that meets the torque, speed, misalignment, space, and environmental demands of your application. Proper selection will ensure efficient power transmission, reliable operation, and extended lifespan of the chain coupling.

editor by CX 2024-05-07

China supplier Giicl Type Cast Steel Curved Tooth CNC Customizable Forged Steel Flexible Jaw Drive Shaft Pipe Connector Drum Gear Coupling coupling constant

Product Description

GIICL type Cast Steel Curved Tooth flexible drive shaft pipe connector Drum Gear Coupling

This shaft coupling is applicable to connecting 2 horizontal line shafting of coaxial line It has a drumshaped teeth shaft coupling with angular orientation compensation on relative deviation of 2 shafts.Temperature of the operating environment is:-20 ~ +80C.The nominal transmitting torque is0.4-4500KN*m.

Gear Couplings

Features:

Improve the starting capability of electric motor, protect motor against overloading, damp shock, load fluctuation and torsional vibration, and balance and load distribution in case of multimotor drives.

Applications:

Belt conveyers, csraper conveyers, and conveyers of all kinds Bucket elevators, ball mills, hoisters, crushers, excavators, mixers, straighteners, cranes, etc.

We can just upload very limited information about our couplings products here, for more info, please do not hesitate to wrtie to us for catalog and related technic info….

A coupling can interchange and replacement with lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Our Company

Ever-power Group specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vacuum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm reducers and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings.

We provides a reliable grantee for the product’ s quality by advanced inspection and testing equipment. professional technical team, exquisite processing technology and strict control system.

In recent years, the company has been developing rapidly by its rich experience in production, advanced management system, standardized management system, strong technical force. We always adhere the concept of survival by quality, and development by innovation in science and technology.

Our Group is willing to work with you hand in hand and create brilliance together!

Material available

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements.

Surface treatment

Blacking, galvanization, chroming, electrophoresis, color painting, …

Heat treatment

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, …

Certifications

FAQ:

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Packing & Delivery

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | OEM |

| Torque: | >80N.M |

| Bore Diameter: | OEM |

| Speed: | 4000r/M |

| Structure: | Flexible |

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as “sliced” couplings while others are known as “slit” couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don’t require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by CX 2023-07-31

China Bulk Supplier of Double Crowned Flexing Gear Coupling for Automobile and Rolling Mills coupling definition

Guarantee: 3 months

Relevant Industries: Producing Plant, Machinery Repair Shops, Meals & Beverage Factory, Building works , Power & Mining, Machinery

Customized support: OEM, ODM

Structure: Gear

Flexible or Rigid: Flexible

Normal or Nonstandard: Standard

Substance: Steel

Diameter: 50-14000mm

Application: Mining and rolling mill equipment, R F K S collection Helical Bevel Gearbox Mining and rolling mill machine

Shape: Spherical

Dimension: 32 to 450

Packaging Particulars: Sea worthy Export packaging

Port: New Delhi

Bulk Provider of Double Topped Flexing Equipment Coupling for Auto and Rolling Mills

We are manufacturers, suppliers, and exporters of Industrial Gear Couplings. These equipment couplings are manufactured with specified distinct features to impart increased bending power to teeth. Hub enamel double topped for enhanced radial & axial misalignment capacity.

We are makers, suppliers of Industrial Gear Couplings. Our CTA couplings selection from dimension 32 to 450 & CTB Couplings from 530 to 820. These gear couplings are manufactured with particular unique functions to impart greater bending power to tooth. Hub teeth double crowned for improved radial & axial misalignment capability.

Costs Could Vary as for every Requirement

Specification

| Product Identify | Gear Couplings |

| Condition | Spherical |

| Substance | Stainless Steel |

| Software | Vehicle, CZPT CZPT Gentle TRUCK Authentic 5 Pace 6SPEED GEARBOX Mining and rolling mill equipment |

| Measurement | 32 to 450 |

| Diameter | fifty – 14000 mm |

Organization Data

Manufacturing facility

Simply click Below to Discover A lot more about Our Organization >> SOUNDPEATS Cyber Equipment Cyberpunk Style Style RGB Light Strip Big Driver Speaker Gaming Method with Mega-S Low Latency Gaming Buds >

Why Pick Us?

Get in Contact with Us

What Is a Coupling?

A coupling is a device that connects two shafts together. It transmits power from one to the other and is used to join rotating equipment. It can also allow for some degree of misalignment and end movement. It is used in mechanical engineering and manufacturing. To learn more about couplings, read this article. Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Mechanical connection between two objectsThe present invention relates to a method and assembly for forming a mechanical connection between two objects. The methods of this invention are suitable for connecting both solid and hollow objects. For example, the method can be used to make mechanical connections between two cylinders. This method is particularly useful for connecting two cylinders that are positioned near each other.

Absorbs vibration

A coupling insert is a part of a vehicle’s drivetrain that absorbs vibrations. These inserts are designed to prevent couplings from moving out of phase. However, the coupling inserts themselves can wear out and need to be replaced. Universal joints are an alternative if the coupling is out of phase by more than one degree. In addition, internal bearings in the coupling need to be lubricated and replaced when they begin to show signs of wear.

Another embodiment of the invention includes a flexible coupling 25 that includes rearwardly-extending lugs that extend toward the coupling member 23. These lugs interdigitate with corresponding lugs on the coupling member 23. They are spaced circumferentially. A first elastic member 28 is interposed between lugs 26 and 27, and is adapted to yield in a counterclockwise direction. As a result, it absorbs torsional vibrations.

Blocks heat transfer

Thermal coupling occurs when a solid block is thermally coupled to the air or fluid passing through it. The amount of heat transferred through a solid block depends on the heat transfer coefficients of the materials. This paper presents a numerical model to understand how heat transfers through different block materials. This work also describes the thermal resistance network for a one-dimensional block.

In some cases, thermal coupling increases the heat transfer mechanism. As illustrated in FIG. 1D, a heatpipe coupler 112 couples two heatpipes 110-1 and 110-2. This configuration allows the pipes to be coupled to the heat source and to the condenser. In addition, the heat pipe couplers may have bellows at the ends to help facilitate linear motion.

Thermal coupling is achieved by ensuring that at least one block is made of a material with a lower thermal expansion coefficient than the annulus. Ideally, the block’s mean thermal expansion coefficient is at least twenty percent lower than the annulus’s mean thermal expansion coefficient. This ensures that the thermal coupling between the two parts is as efficient as possible.

Another type of thermal coupling is achieved by using flexible elements. These are often washers or springs. These components allow the blocks to maintain physical contact with the post 55, which means that the heat transfer is more efficient even at higher temperatures. The flexibility of these elements also makes it possible to choose an element that will not impede assembly.

Protects rotating equipment

A reliable, long-lasting coupling system can reduce the risk of damage to rotating equipment. Designed to protect against torque overload and wear, Voith torque-limiting couplings provide outstanding safety and reliability. As a result, they can deliver maximum performance and minimize equipment downtime. In addition to their long-term benefits, these solutions are ideal for applications where safety and reliability are of paramount importance.

A good coupling provides many advantages, including the ability to transmit power, compensate for axial movement, and absorb shock. It is essential to choose the proper coupling for your application based on the basic conditions of your rotating equipment. For example, if you have two shafts with parallel rotation axes, you should choose a parallel coupling. Otherwise, you should use an angular coupling.

Torque-limiting couplings can also provide protection for rotating equipment by disengaging at a specific torque level. This protects the drive shaft from undergoing catastrophic failure. Torque limiters are particularly helpful for high-value equipment. By preventing catastrophic failure, you can avoid expensive repairs and minimize equipment downtime.

Coupling guards are easy to install and provide effective protection for rotating equipment. These covers are made of sheet metal bent to fit over the shaft. They are durable and easy to remove when necessary. This type of guard can prevent employees from catching their hands, tools, or loose clothing on motor coupling components.

editor by czh 2023-02-22

China manufacturer & factory supplier for Buy in Arak Iran oem china company electric worm wheel drive working gear reduction box variator motor With high quality best price & service

corrosion- and put on-resistant coiled tubing injector roller chain assemblies for the oil and gas industries. Obtainable in single and double pitch travel chain sorts with different sizes and energy score. Features incorporate zinc-nicWe warmly welcome the friends from all the planet!kel and non-hexavalent chromate protecting exterior coating, electrochemically bonded, and interference in shape include plates. The group is centered on making all assortment of regular roller chains and sprockets, gears & gearboxes, this kind of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just offered its goods all in excess of china, but also marketed a lot more than 65% merchandise to oversees, like Europe, America, South-east Asia, and it also has established up storage logistics in places like Europe.

Overview

Fast Details

- Relevant Industries:

-

Design functions

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

one.5~118Nm

- Input Speed:

-

1400/min

- Output Velocity:

-

880~1000/min

- Model Identify:

-

OEM

- Solution identify:

-

drive doing work equipment reduction box variator motor

- Application:

-

Foodstuff Stuff, Ceramics, Chemical, Packing, Dyeing, Wooden functioning, Glass.

- Shade:

-

Blue(RAL5010)/Silver gray (RAL9022) Or On Ask for

- Ratio:

-

Upkeep This sort of equipment reducer is supplied with a permanent lubrication, so it does not want any type of upkeep.

1.4~7

- Warranty:

-

one Yr

Offer Potential

- In our organization we are mindful of the significance of the users’ basic safety. That is why our PTO’s are developed in accordance to authorized laws and European directives and bear the CE signal. A key issue for security assurance is the accession in the products’ improvement stage. By all signifies, the users’ information about the right use of a PTO generate shaft is crucial. This indicates, that each and every users’ duty is to read through and follow the security directions.

- Supply Potential:

- 36000 Piece/Pieces for every Thirty day period

Packaging & Shipping

- Packaging Information

- Transparent box packaging, or shade box packaging, it also can be tailored.

- Port

- Ningbo/Shanghai

On the internet Customization

Get oem china organization electrical worm wheel generate functioning equipment reduction box variator motor

Q1.How to pick a variator motor which meets our requirement?

A1: You can refer to our catalogue to pick the gearbox or we can assist to choose when you provide

the specialized details of output torque, output velocity and motor parameter etc.

Q2.How is your price tag? Can you supply any low cost?

A2: We will give the greatest price we can foundation on your needs and the portions.

Q3.Do you offer any visiting?

A3: Of course! We sincerely invite you to check out us! We can decide you from airport, railway station and so on.

Also, we can prepare housing for you. Remember to allow us know in superior.

This autumn.When is the ideal time to speak to you?

A4: You can contact us by email any time, we will reply you as soon as possible.

Q5.How extended will it take for the lead time?

A5: For our regular product, please refer to the distinct product webpages to check out the lead time.

For the OEM/ODM products, you should get in touch with us for more information.

China manufacturer & factory supplier for factory in Paris France manufacturer for High quality custom pinion gear planetary spur for tractor With high quality best price & service

ISO 9001 licensed manufacturer of precision roller chains. Sorts include one and numerous strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. we have acquired the believe in of buyers throughout the world. a specialised provider of a total selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

- Relevant Industries:

-

Manufacturing Plant

- Solution Keywords and phrases:

-

custom pinion equipment,planetary equipment spur Owing to these functions, normal worm gear apps contain presses, small engines, lifts and elevators, rolling mills, conveying engineering, mining sector devices, on rudders, and worm travel saws.equipment,gear for tractor

Source Capability

- Source Capacity:

- 5000 Piece/Items per Thirty day period

Packaging & Shipping and delivery

- Packaging Particulars

- Neutral paper packaging, wood boxes for outer box or in accordance to customer’s need.

- Port

- Shanghai Port / Ningbo Port

On-line Customization

The good quality of products is for us and for our clients of higher significance. This is why we use European manufactured elements in our goods. We also complete consistent manage of incoming supplies and the control of finished goods. In our organization we operate in accordance to ISO 9001.

We At any time-Electrical power Team with 4 branches in excess of 1200 personnel is 1 of the largest transmission elements and machining things makers in China

Merchandise Description

Product Description:

We specialised in producing auto gears , motorbike gears, gearbox, specific vehicle (energy takeoff, snowmobiles, engineering automobiles) gears, generator add-ons, stainless metal ice crusher and so forth.

|

Substance |

1020,1045,20CrMnTi, and so forth. |

|

Machining Procedure |

Gear Hobbing , Gear Shaping, Gear Shaving, Equipment Grinding |

|

Modules |

one., 1.25, 1.5, 1.75, 2., 2.25, 2.5….8. and many others. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

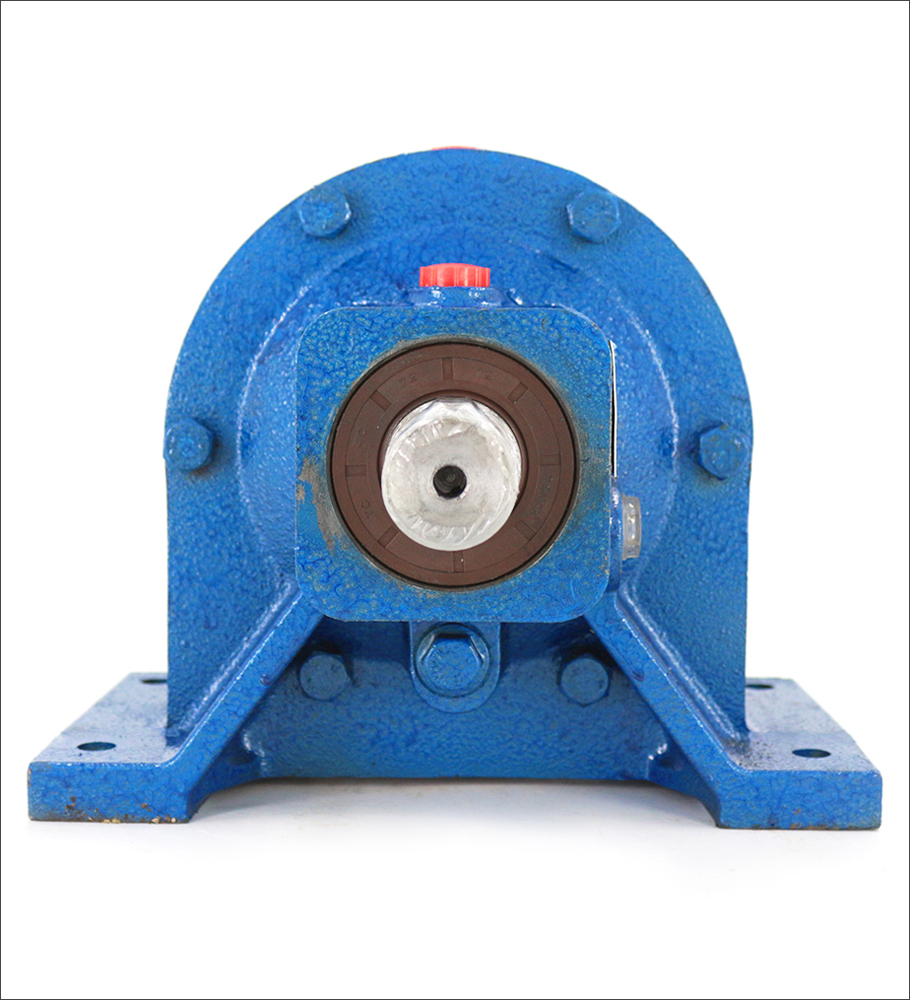

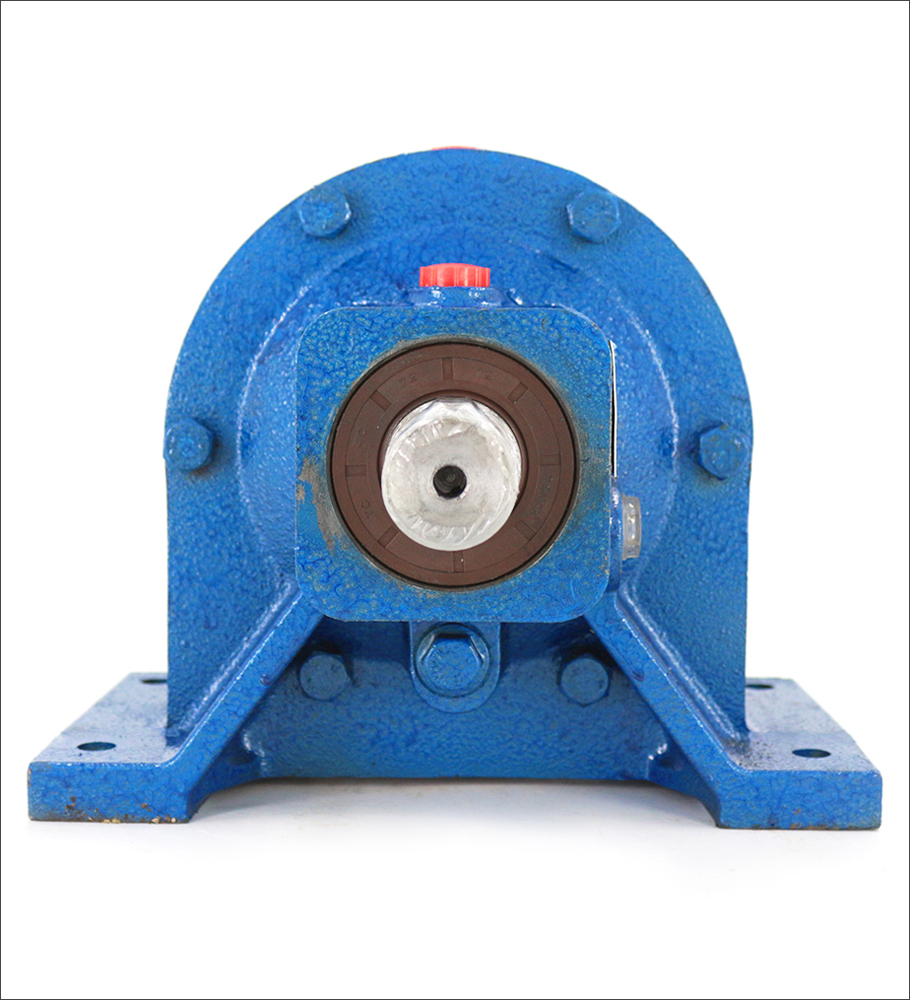

China manufacturer & factory supplier for China in Kerman Iran manufacturer for cycloidal pin wheel gear reducer for conical mixer machine With high quality best price & service

Distributor of precision roller chains manufactured from carbon metal. Accessible with .two hundred to 1.875 in. roller dia. Flat top, multi-flex and conveying chains are also supplied.EPG will constantly adhere to it organization spirit of becoming practical, revolutionary, effective and outstanding to make the best global transmission generate.

Overview

Quick Specifics

- Applicable Industries:

-

Production Plant

Worm gears are the most compact type of technique and give high-ratio velocity reduction. They are usually the desired sort of gearing system when area is restricted and big equipment reductions are required. Worm gears can be utilized to possibly greatly increase torque or greatly reduce speed. They are also the smoothest and quietest of the equipment methods, as prolonged as they are correctly mounted and lubricated.

- Brand Identify:

-

OEM

- Merchandise NO:

-

SYF

- Model Amount:

-

R

- cycloidal gearbox:

-

Cycloidal Gearbox Reducer

- Color:

-

Blue

- Product name:

-

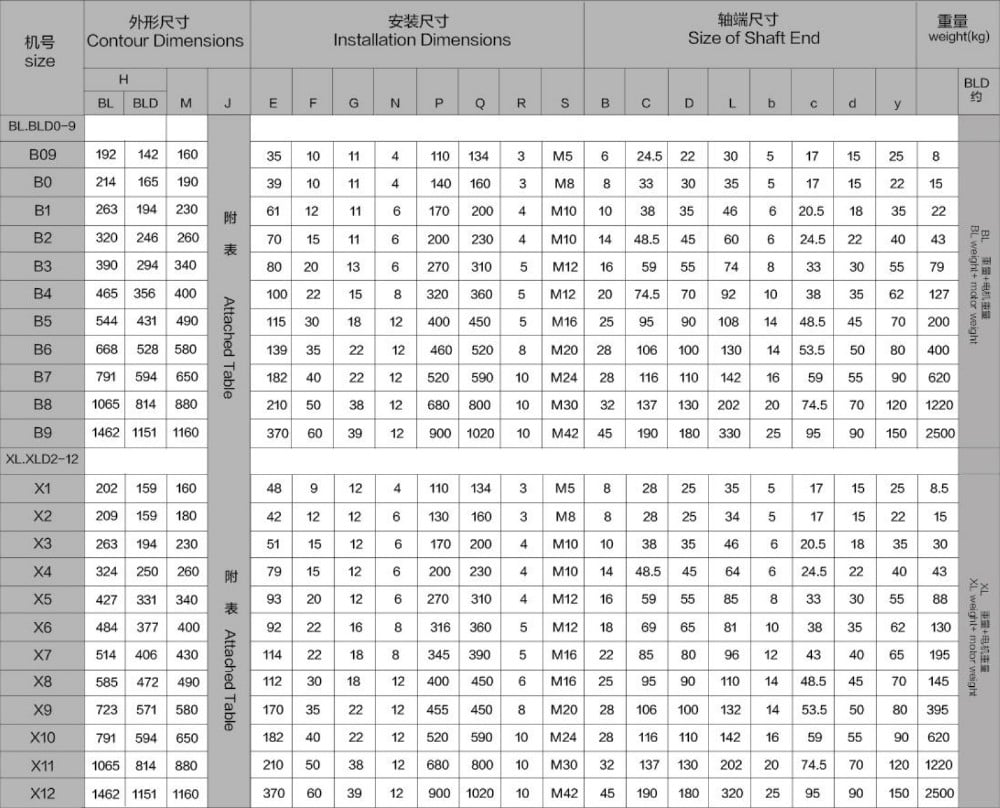

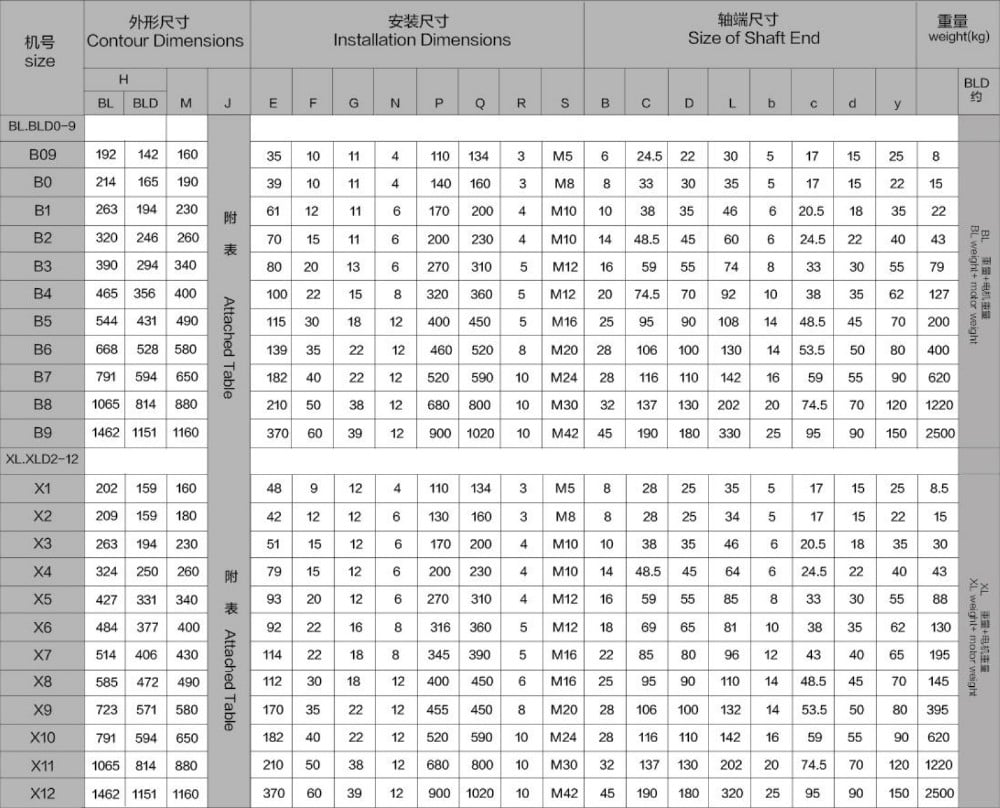

BLD Cycloid Pace Reducer

EPG manufacturer rotocultivator ploughshares in T. line have been selected as the Nationwide Rotary Tillage Machinery Sector “Best Brand Goods” in 2007 by Rotocultivator Department of China Agricultural Machinery Sector Association.

- Software:

-

Machine Device

- Content:

-

Aluminium Alloy

- Bearing:

-

NSK

- Certification:

-

ISO9001

- Ratio:

-

nine-28800

Offer Capacity

- Source Potential:

- 1200 Set/Sets per Thirty day period Cycloidal pinwheel gear pace reducer gearbox

Packaging & Shipping

In our revenue plan we offer regular and vast-angle PTO travel shafts. Regarding the customers’ requirements there are various sizes, lengths and security aspects (clutches) obtainable.

- Port

- Shang hai

On the web Customization

Merchandise Description

Cycloidal equipment reducer is a principle adopted K-H-V Planetary Equipment less revolutionary equipment. Its transmission process as follows : enter shaft outfitted with a a hundred and eighty-degree dislocation of the double eccentric sets, changed with two eccentric turn as a roller bearing arm, the development of H-, two cycloid spherical gap at the heart shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing period, comprising a variation of the tooth meshing with the gearbox.

|

Variety |

phase |

Product |

Ratio |

Nominal Energy (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal Reducer |

Single reducer |

B09/X1 |

9-87 |

.fifty five-.18 |

26-fifty |

|

B0/X2 |

1.1-.eighteen |

fifty eight-112 |

|||

|

B1/X3 |

.55-.eighteen |

117-230 |

|||

|

B2/X4 |

four-.55 |

210-four hundred |

|||

|

B3/X5 |

11-.fifty five |

580-1010 |

|||

|

B4/X6/X7 |

11-2.2 |

580-1670 |

|||

|

B5/X8 |

eighteen.5-2.two |

1191-3075 |

|||

|

B6/X9 |

15-5.five |

5183-5605 |

|||

|

B7/X10 |

eleven-forty five |

7643 |

|

Variety |

stage |

Design |

Ratio |

Nominal Electricity (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal reducer |

Double reducer |

B10/X32 |

99-7569 |

.37-.18 |

175 |

|

B20/X42 |

1.1-.18 |

600 |

|||

|

B31/X53 |

two.2-.25 |

1250 |

|||

|

B41/X63 |

two.2-.25 |

1179-2500 |

|||

|

B42/X64 |

4-.55 |

2143-2500 |

|||

|

B52/X84 |

four-.55 |

2143-5000 |

|||

|

B53/X85 |

7.5-.fifty five |

5000 |

|||

|

B63/X95 |

7.5-.55 |

5893-8820 |

|||

|

B74/X106 |

11-2.2 |

11132-12000 |

|||

|

B84/X117 |

11-2.two |

11132-16000 |

Principal Attributes

All planetary cycloidal reducer rotating device can be divided into 3 components:input element,deceleration element and output part.

Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,geared up with two ball bearings on the eccentric sleeve,the development of H two cycloid gear middle gap is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid equipment and pin gear ring of equipment meshing,considerably less undesirable tooth meshing reduction system to form,(in buy to reduce friction,in little ratio of pace reducer,the needle with needle enamel on the equipment established).

When the input shaft with eccentric sleeve rotation for a 7 days,as a result of the cycloid gear tooth profile curve traits and restricted by needle on the gear enamel,the movement of the cycloid equipment turning out to be both revolution and rotation of the plane motion,and input shaft are

produced for a week,eccentric sleeve also change the week,cycloid equipment in the reverse course around a massive tooth big difference reduction is acquired, then with the aid pf W output system,the cycloid equipment rotates at minimal speed motion through the pin shaft,passed to the output shaft,low output speed can be accomplished.

Traits:

1.Cycloid reducer massive reduction ratio, higher effectiveness: a reduction gear ratio is 9~87, the two-phase reduction gear ratio is 121 ~ 5133, multistage mix can achieve tens of countless numbers, and the needle tooth meshing line variety rolling friction, the meshing area no relative sliding, so a reduction efficiency of 94%.

2.Pin wheel reducer clean working, minimal noise: the enamel make contact with at the very same time when in procedure, the coincidence degree high, steady running, strong overload capacity, minimal vibration and sounds, a selection of designs, little sound.

three. The use of reliable, extended daily life: simply because the main portion is produced of higher carbon alloy steel quenching (HRC58-62), and then grinding, and cycloid equipment and pin equipment established mesh transfer to the pin equipment form rolling friction pair, friction coefficient is little, so that the meshing zone no relative sliding, wear tiny, so tough.

four. Compact structure, tiny volume: in contrast with other reducer with the power of the over excess weight, modest volume 1/3, as is the planetary transmission, the input shaft and the output shaft in the identical axis, in get to get the smallest attainable size.

Our Company

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a present company integrating improvement, layout, creation and sales,Principal promoting products include reducer motor,water pump,design machinery and parts,bearings,components and electrical tools,plastic goods,Labour defense appliance.Our firm usually comply with the procedure concept which is made up of people-oriented, innovation as the soul,be geared up for hazard in times of peace, unremitting……

Software area

Certifications

Income territory

Packing & Shipping and delivery

|

Packaging |

|

|

Dimension |

500 (L) * 500 (W) * four hundred (D) |

|

Fat |

1.2 T |

|

Packaging Information |

The normal bundle is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe movie for packing or pack it in accordance to buyers special request. |

|

Packaging |

|

|

Dimension |

500 (L) * five hundred (W) * 400 (D) |

|

Fat |

1.2 T |

|

Packaging Particulars |

The normal deal is picket box(Size: L*W*H). If export to european countries,the wood box will be fumigated.If container is also tigher,we will use pe film for packing or pack it according to buyers specific ask for. |

FAQ

Q1: Are you buying and selling organization or producer ?

A: We are a maker in ZJ China.welcome to our manufacturing unit to have a check out.

Q2: How we decide on models and technical specs?

A:You can email us the sequence identify & code (for illustration: WJ collection worm gearbox) as properly as prerequisite particulars, this kind of as motor energy, output pace or ratio, provider issue or your application…as much info as achievable. If you can supply some images or drawings, it is far better.

Q3: How is your price tag? Can you supply any price cut?

A: We will give the greatest cost we can foundation on your requirements and the portions.

This autumn: How lengthy must I wait around for the comments soon after I ship the enquiry?

A: Inside of twelve hrs.

Q5: What is your solution warranty period?

A:We supply 1 year guarantee because the vessel departure date still left China.

Q6: What industries are your gearboxes becoming used?

A:Our gearboxes are commonly applied to metallurgical equipment, mining gear, automation products, foodstuff machinery, packaging equipment, tobacco equipment and so on.